Jill and I had a great weekend in the shop. Not as many hours as we would have liked, though -- only a few hours yesterday, and about 4 hours today. But I'm pleased with what we accomplished.

Jill squared up the corners on our mortises in the headboard top rail. It's a bit tricky, because any small error will leave a gap. Jill was frustrated at first because they weren't coming out perfect, and when I showed her how to do it so there's no gap, I think I saw a few tears. I felt bad for her, but I'm glad she is so focused on getting everything perfect. She got the hang of it soon enough, and most all of them came out without any visible gap. The couple that have a small gap are easily repairable.

We milled up the spindles. In fact, we got to mill them several times. The first time, I made them too small. DOH! So I milled them again, and this time they twisted and warped severely by the time we got them finished. All wood warps and twists a bit when you mill it, and so we take precautions to account for that and ensure that the final product is flat and square. But this set of spindles warped and twisted so badly that there was no rescuing it. So I milled them again, and this time I went extreme in my precautions. I started by milling each spindle 1/2" oversize in all directions. Then I planed them a bit, and jointed them again, then planed them again. I still had a little warp in one piece, but it won't affect anything and it won't be noticeable.

Once we milled the pieces, I used a handplane to make each one fit perfectly in the mortises Jill cut. And here is the finished product, which each spindle sitting about 3/8" deep in it's mortise.

Not too shabby. When they are cut this precisely, it doesn't look like the spindle sits in a mortise -- it looks like it is sitting flush on the rail, which is the look we want. There are a couple rails that have a tiny gap, but we'll fill the gaps with a little sawdust and glue and they won't be noticed. Of course, all of those pencil lines will be gone, and all that remains will be perfect, gapless joints.

We have not yet cut the profile for what will be the top of the top rail (which is on the bottom in these pictures). Generally speaking, we always cut joinery before we cut profiles, because it's much easier to get the joinery right on flat wood than on curved wood. In the below picture, for example, you can see the blue marker line on the rail, which represents the final profile on the top side of the rail. If we had cut that already, it would be difficult to work with this piece. Right now, the flat side sits easily on the bench while we work on the rail. The flat side also gives me a straight edge which I can use to register my cuts on the multi-router. This would be next to impossible if I had already cut that profile. I did, of course, profile the edge that mates to the spindles, because I have to get my mortises to the correct depth, and the depth needs to register from the final profile.

Next, we had to cut a dado in the rail to accept our veneered panel. This was really tricky. The spindles on each side of the panel have a dado that the panel slides into, and the dado in the rail has to line up dead-on exact with the dados in the spindles, or there will be gaps. I'm happy with how it came out. So you have a little context, the following pictures are pictures of the top section of the headboard upside-down. (If that's difficult to perceive, hold your monitor upside-down, and now you will be looking at the top half of the headboard.)

We had a bit of a safety adventure cutting the dado for the veneered panel. When I finished making one of the cuts, we turned the router off, and Jill started vacuuming out some of the sawdust with our ShopVac. The router was still spinning down, and she bumped the vacuum hose into the router bit. The router bit grabbed the vacuum hose and gave it a good yank, and it freaked Jill out (as it should). She didn't get hurt, but it gave her a scare. And it gave me a scare too. Good will come of this, though. I'm a safety nut in the shop, and over the past few weeks, I have sometimes been frustrated that Jill doesn't have enough respect for the danger that these tools present. I don't think she appreciates just how easily they hurt you if you aren't being careful. One rule I follow is that when I turn off a tool, I stand there and watch the blade or bit until it stops turning, and I don't do anything until then. That rule ensures that I am aware of whether the blade is still spinning, and that I don't do what Jill did today -- start sticking my hand where it doesn't belong when a sharp blade is still spinning. Jill did the same thing at the tablesaw last week -- after I made a cut and turned off the saw, she reached in to grab the off-cut while the blade was still spinning. I yelled pretty loud, and she pulled her hand away before any damage was done. So now she has had two lectures from me on keeping her hands away from spinning blades even after the tool has been turned off, and she has had one good scare that came from ignoring that advice. Hopefully her scare today will keep her on her toes.

Back to the project.

The spindles and panels are currently too long. That's intentional. The last thing I will do on the headboard joinery is to trim these pieces to their correct length. I have to get everything else complete and in place to know how long the spindles and panels need to be. If I mess up that dimension, I have to make the spindles and panel all over again. My blood pressure went up a few notches just thinking about that prospect. Yikes.

I'm fairly pleased with the repair of the veneered panel (remember, I cut too much on one side and not enough on the other side). The veneers now meet in the middle of the panel, and the repair is hidden in the dado of the spindle.

Notice the happy face on the rail, which you can see in the photo below. (The happy face is upside down here). This is a trick I learned from William Ng. William owns the William Ng School of Fine Woodworking in Anaheim, CA, and he is a wonderful craftsman. He taught me to put a happy face on the "show" face of every part. The happy face tells me which side goes in which direction, and also which side goes up. So, right after I milled the top rail, I drew a happy face on it in permanent marker on the side that will be toward the mattress. Now, I can immediately see which side of the rail goes to the mattress, and which direction is right-side up. Since the happy face is down in this photo, I know that the rail is upside-down. At this stage, it's pretty obvious which side is right-side up, but when I was milling it, it would have been easy to make a mistake. It's difficult to see in this photo, but the grain in the top rail arches in the same direction that the final shape of the rail will arch, and that will be very obvious (and cool) once the finish is applied. It would have sucked to get it upside-down. So the happy face kept me from messing it up.

In addition to the happy face, every piece is labelled, and every mortise in the rail is numbered so that I put the right spindles in the right mortises. So, in the picture below, the spindle to the right of the panel is "H5," which means that it is Headboard Spindle #5. There is a corresponding #5 on the rail just below the mortise. The spindle also has a happy face (not visible in this picture), so I know that this face of the spindle goes on show face, and that I know which end goes up. Labelling is critical. There are 34 pieces of mahogany in this bed, and many of them look very similar to one another. I take a lot of time selecting the grain that each piece will have, as well as orienting the grain, and making each joint perfect. So I have to keep careful track of which part is which, and how to orient each part.

At this point, I start getting pretty excited about how the final product will look. It may not look like much now. The boards are mostly square, and none of them are sanded. There are ugly pencil lines and permanent marker labels and happy faces everywhere. There are no ebony plugs, splines, roundovers, or other details. And no finish. But it's coming together very nicely. It's going to be very cool.

Once were finished cutting the joinery for the top rail and spindles/panel, it was time to start shaping the top board of the bottom rail. There are three bottom rails, and the top one needs to match the profile of the top rail. Again, normally we cut profiles after we cut jointery, but that's not possible here because the spindles have to mate to the profiled edge of the bottom rail. Here is the bottom rail cut to shape, and a picture of the top rail sitting on top of the bottom rail to compare their profiles. We cut the profile using the same template method we used on the top rail and legs: First, we screwed the template to the board, then we cut close to the line at the bandsaw, then we used a template bit at the router table to make it match the template perfectly.

The white patch on the left edge of the top rail in the above photo is masking tape. I put that tape there when I was cutting the profile of the top rail on the router table. The will be a curve detail at the joint between the top rail and the leg, and I need to leave extra meat on the rail and leg for that detail. (More on that later.) It's easy to forget those sorts of things when you are cutting profiles, so I put masking tape there to remind myself not to cut that area.

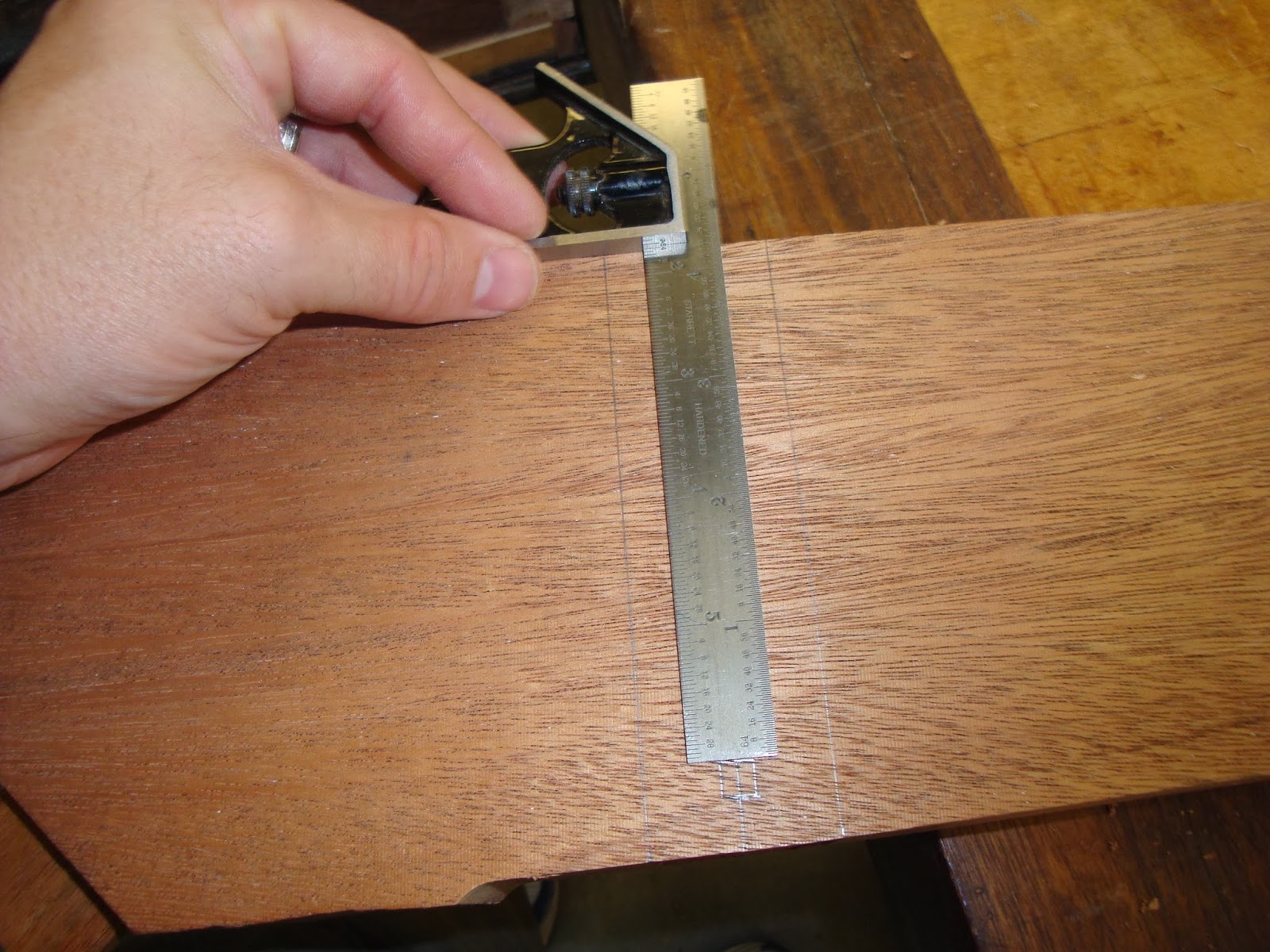

Once we had the bottom rail cut to shape, we transferred the lines from the top rail to the bottom rail, which the picture above shows. The lines need to match the top rail exactly, because these lines define where the mortises go, and the mortises have to be matched exactly on the top and bottom rails or else the spindles will be crooked. Crooked is bad.

We wrapped up the evening by setting up the multi-router to cut the mortises in the bottom rail. This setup has to be very precise. Normally, I prefer to cut the mortises first and then mill the tenon (in this case, the spindle) to match the mortise. It's easy to shave just a little bit more off the tenon/spindle to fit perfectly into the mortise, and much more difficult to cut the mortise to perfectly fit a pre-made tenon/spindle. But for a variety of reasons, that wasn't possible here. So we have to cut the mortise perfectly to match the spindle. We spent about 30 minutes setting up the multi-router and cutting a test-mortise on a piece of scrap, and it fit perfectly. Then we stopped. It's been a long day, and cutting tricky joinery at the end of a long day is a recipe for problems. I'll check everything once more tomorrow, and we'll cut the joints then.

This is where it gets very exciting. Once we cut the joinery for the spindles on the bottom rail, we just have a few fun details to cut and then we're ready for sanding and glue-up on the headboard! And then another 50 hours on the footboard, and another 60-70 hours finishing, and we'll be done. By the time we're finished, Jill and I will probably have a combined 350-400 hours in this bed. Doing it myself would take about 250-275 hours. This is Jill's first woodworking project, so things take her a bit longer. But it's a lot more fun with her.